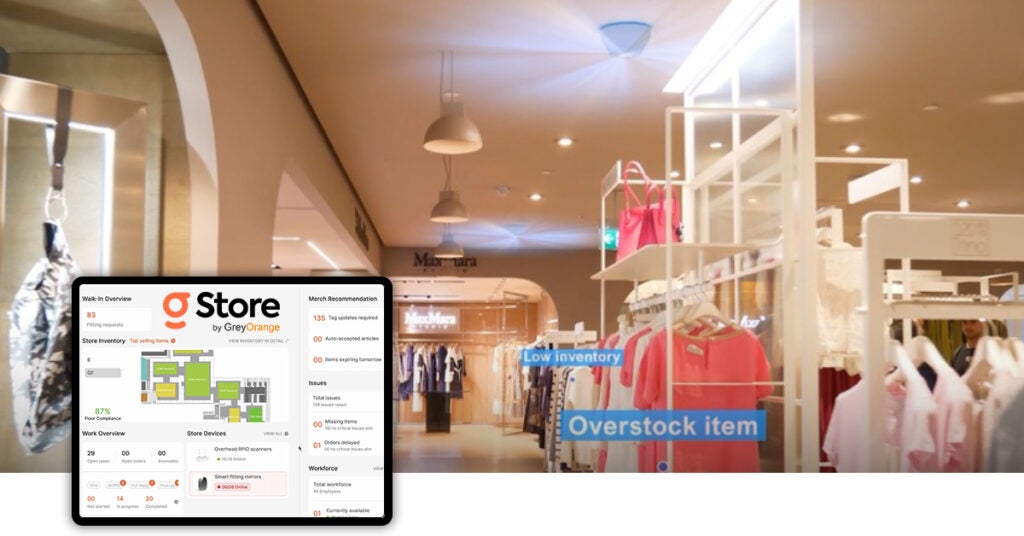

According to Gartner, “Store inventory is at the heart of retailers’ enterprise-wide inventory management and is critical for excellent execution of unified retail commerce. Retail CIOs can use this research to navigate the store inventory management application landscape to prioritize investments that are aligned with business needs.” The report also notes that, “AI-based intelligence will be the single biggest influence on retailers’ ability to discern real-time inventory feeds from their stores, as well as other inventory sources.”

Check out the Gartner Market Guide for Retail Store Inventory Management Applications, 2023

This report offers a detailed analysis of the future needs of end-users.

This 2023 Gartner Market Guide for Retail Store Inventory Management Applications recommends that CIOs:

“AI-based intelligence will be the single biggest influence on retailers’ ability to discern real-time inventory feeds from their stores, as well as other inventory sources.”

– Gartner Market Guide for Retail Store Inventory Management Applications, 2023

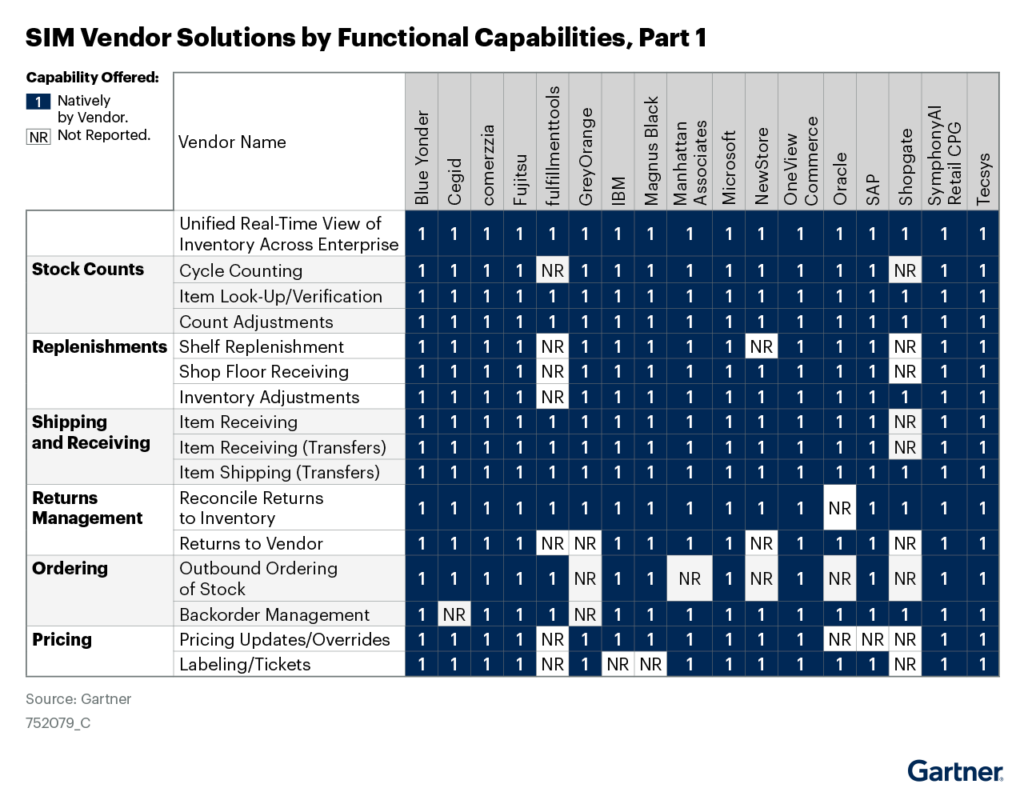

Gartner, Market Guide for Retail Store Inventory Management Applications, Sandeep Unni, 6 November 2023

GARTNER is a registered trademark and service mark of Gartner, Inc. and/or its affiliates in the U.S. and internationally and is used herein with permission. All rights reserved.

Gartner does not endorse any vendor, product or service depicted in its research publications, and does not advise technology users to select only those vendors with the highest ratings or other designation. Gartner research publications consist of the opinions of Gartner’s research organization and should not be construed as statements of fact. Gartner disclaims all warranties, expressed or implied, with respect to this research, including any warranties of merchantability or fitness for a particular purpose.

This graphic was published by Gartner, Inc. as part of a larger research document and should be evaluated in the context of the entire document. The Gartner document is available upon request from GreyOrange Inc.