Scale and locate conveying and sorting robots as demand requires

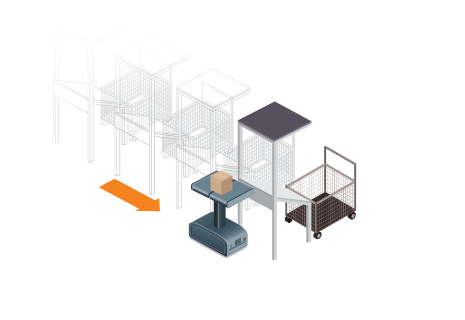

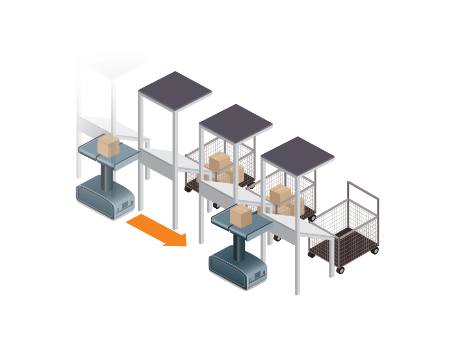

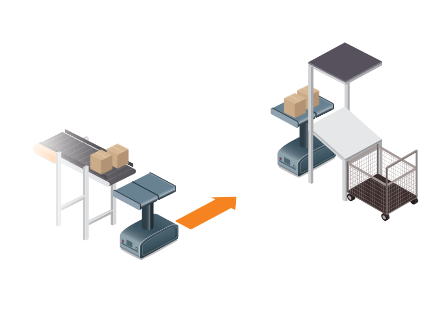

Our fleet are flexible, scalable fleets used for conveying & sorting packages or inventory from receiving through dispatch without bottlenecks or rigidity.

In today’s fast and fluctuating commerce landscape, businesses can’t afford the restrictions of rigid conveying and sorting systems. Once locked-in, these systems can’t flexibly adapt and scale with demand patterns and business changes.

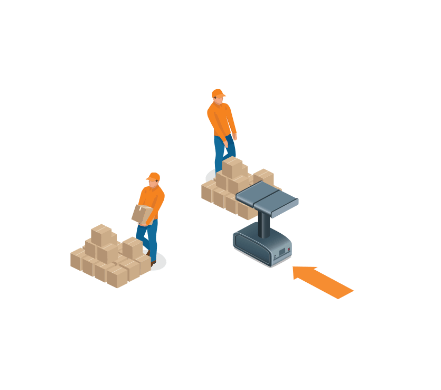

Ranger™ MoveSmart can augment or even replace rigid systems to deliver scalable and portable conveying and sorting systems as you need it, where you need it, especially when handling peaks. Capable of operating in footprints where rigid systems won’t fit, Ranger MoveSmart helps you optimize current facilities, plus can easily relocate to other facilities as you grow.